Compatibility with pasta machine thickness settings

We know that many people use pasta machines to roll out their clay and that the values may vary depending on the brand. To help you choose the right thickness, here is a reference of the approximate thicknesses based on our experience with polymer clay—once conditioned, baked, and cut on a tile.

| Setting | Marcato Ampiamotor |

|---|---|

| 0 | 3.20 mm |

| 1 | 2.90 mm |

| 2 | 2.60 mm |

| 3 | 1.95 mm |

| 4 | 1.75 mm |

| 5 | 1.40 mm |

| 6 | 1.15 mm |

| 7 | 0.80 mm |

| 8 | 0.75 mm |

| 9 | 0.70 mm |

Frequently asked questions about polymer clay slab thickness in jewelry

This happens with cutters made without specific knowledge of 3D tool design or moldable materials. A properly designed cutter has sharp edges that leave no residue or only a minimal one. These are delicate tools and require proper care. If you choose low-quality cutters, your post-processing work (sanding and polishing) will be much greater, and in some cases, even after sanding, you may still end up with uneven and unprofessional edges. Choose high-quality cutters that will last longer and deliver better results.

The thicker the piece, the more time it may need in the oven to fully cure. Thin pieces can be baked with less risk of bubbles or cracks but should be handled carefully to avoid breaking after baking. For thin pieces placed on a tile and covered with foil, you can lower the temperature and bake for a longer time.

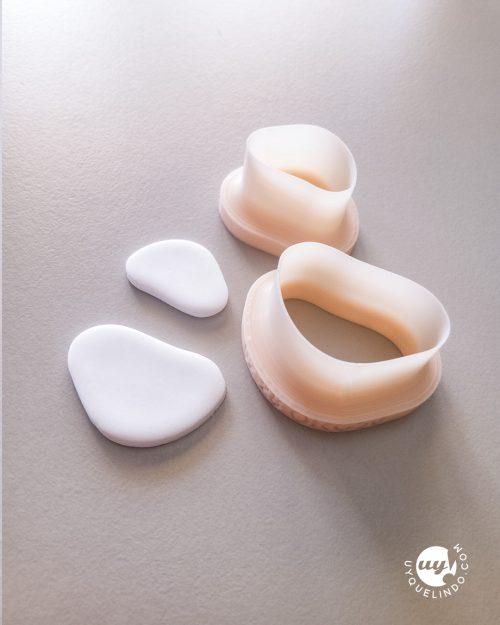

Yes, thicker clay requires more pressure for a clean cut. This is especially important when working with ceramics (clay), as the material is thicker and more resistant. We can adapt any of our models for this purpose and create a custom cutter for you.

For thin thicknesses, it is best to apply even pressure and remove the cutter carefully to avoid deformations.

In all cases, by applying even pressure with an acrylic or wooden piece, you will achieve an effective cutting and stamping process while reducing strain on your hand joints.

Thicker pieces tend to be more resistant but also heavier. In very thin pieces (less than 2 mm), the risk of breakage increases if they are not baked properly or subjected to pressure. Well-conditioned and properly baked clay achieves flexibility in thinner sheets without breaking.

Yes, especially those with relief. A stamper can compress and displace the clay, slightly reducing the final thickness or raising the surface to varying degrees. In such cases, it's recommended to start with a thickness greater than the desired one to compensate for the compression, or conduct tests with different thicknesses until the desired result is achieved.

Los cortadores-estampadores que consigues en el mercado están usualmente preparados para cortar y estampar de 3 a 4 mm, pero en espesores muy delgados (2 mm) obtendrás una estampa poco definida. Nosotros ofrecemos cortadores-estampadores adaptados a los espesores más delicados (CORTE FINO a partir de 2,5mm) o con las medidas tradicionales (REGULAR a partir de 3mm). Elige tu favorito al momento de comprar y consúltanos si tienes dudas al respecto.

It’s important that the clay is well-conditioned for fine cuts (not sticky, with the right consistency and flexibility). You should also roll it out on a smooth surface to prevent it from sticking or deforming when cutting.

Depende de la marca de la máquina pero en líneas generales es el 2. Recomendamos hacer pruebas propias y medir con calibre una vez que la pieza esté cocida, pues cada máquina puede variar ligeramente.

Between 2 and 2.5 mm. This thickness maintains the lightness without compromising the strength of the piece.

It depends on the final use of the piece:

Lightweight earrings: 2-2.5 mm

Regular earrings, dangles, or structural pieces: 3-4 mm

Broch bases: 3-4 mm or even thicker if rigidity is needed or if your design explores volume and depth.

If you're using a pasta machine, check the thickness table according to the brand.

What thickness corresponds to each setting on my pasta machine?

Thickness may vary depending on the brand, but here’s a reference based on the most popular models.

Are these measurements exact?

Not always. Each model and brand may have slight differences. As you’ll see in the table, some machines have an inverse numbering system for thickness settings.

IMPORTANT

The measurements published in the tables are those provided by manufacturers for edible pasta, but polymer clay has a different resistance. Its behavior when passing through the machine may result in variations in actual thickness.

For a precise measurement, we recommend using a caliper to measure a clay sheet after cutting, baking, and rolling it through each setting. We have tested this ourselves using the Ampiamotor model from Marcato, obtaining real results that can be used as a reference. Keep in mind that clay slightly shrinks when baked due to moisture loss.

Additionally, embossing cutters compress and shift the clay, which may create areas with increased thickness. The best approach is to experiment and find the volume relationship that best suits your final design.

These are the values published by the manufacturers.

| Setting | Marcato (Ampiamotor, Atlas 150, etc.) | Imperia | Sculpey | Standard budget-friendly machine |

|---|---|---|---|---|

| 0 | 4.8 mm | – | 3.9 mm | 4.8 mm |

| 1 | 3.7 mm | 0.6 mm | 3.2 mm | 3.8mm |

| 2 | 3.1 mm | 1.2 mm | 2.8 mm | 3.3 mm |

| 3 | 2.4 mm | 1.8 mm | 2.3 mm | 2.5mm |

| 4 | 1.8 mm | 2.4 mm | 1.9 mm | 1.9 mm |

| 5 | 1.5 mm | 3 mm | 1.5 mm | 1.5 mm |

| 6 | 1.2 mm | 4 mm | 1.2 mm | 1.2 mm |

| 7 | 1 mm | – | 1 mm | 1 mm |

| 8 | 0.8 mm | – | 0.8 mm | 0.8 mm |

| 9 | 0.6 mm | – | 0.6 mm | – |

This is the result of our experience using the Marcato Ampiamotor model.

After conditioning, cutting, and baking each piece.

| Setting | Marcato Ampiamotor |

|---|---|

| 0 | 3.20 mm |

| 1 | 2.90 mm |

| 2 | 2.60 mm |

| 3 | 1.95 mm |

| 4 | 1.75 mm |

| 5 | 1.40 mm |

| 6 | 1.15 mm |

| 7 | 0.80 mm |

| 8 | 0.75 mm |

| 9 | 0.70 mm |

We invite you to check out the new questions we've added to our FAQs, which you can find here. Do you have more questions? You can leave your doubts in this form, and we’ll add all that information to the FAQs on our special page. Follow our social media to stay updated on the latest additions!